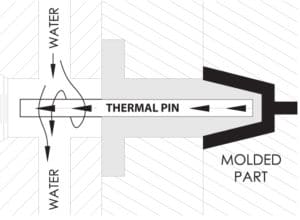

Thermal Pins are high temperature heat pipes and are used in a variety of molding equipment – injection molding, blow molding, extrusion molding and thermal form molding industries. Noren offers different ways to use the Thermal Pin heat conductors – you can either insert the Thermal Pin into your existing core or we can make your core into a Thermal Pin heat conductor by processing your cores at our manufacturing facility. The function of our Thermal Pin heat conductors is to remove heat very quickly which reduces cycle times resulting in increased yields.

Injection / Blow Molding

Injection / Blow Molding

In small cores, thermal pins enable cooling in areas previously inaccessible to water cooling. In solid cores, you can draw heat from the plastic to the mold base or to remote water channels. Most solid core applications pay for themselves in 4 to 12 weeks.

In blow molding, the hollow THERMAL PIN heat conductor uniformly cools the end of the blow pin. Hollow THERMAL PIN heat conductors evenly cool the necks of blow molded bottles.

Extrusion / Rotational Molding

Extrusion / Rotational Molding

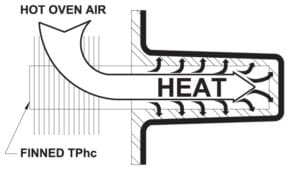

Because THERMAL PIN heat conductors are virtually isothermal, not only do they transfer heat fast, they do it evenly. They eliminate hot spots which cause sink marks, pulling and spotting.

THERMAL PIN heat conductors transfer heat from rotational and rubber molds to heat the plastic more quickly and evenly, regardless of variations in mold thickness.

Have Questions? We're Ready to Help!

Products

Noren thermal solutions are designed to cool overheating electronics in a variety of industries and applications. Check out our PRODUCTS section for more information.